The ‘last mile’ is a crucial step in the supply chain – it is the process of getting goods to arrive at their final destination, whether it is a residence or commercial business. Historically, the simplest form is via delivery by a box truck or local mail carrier. Yet despite emerging technologies and automated delivery systems, the 2020 increase in online shopping and next-day shipping has made this last step quite a difficult one for companies. Today, most major brands are exploring new ways to cut down on delivery times and create a more efficient process.

Box Trucks versus Drones

While a typical box truck has greater hauling capacity and few problems navigating suburban streets, using these as delivery methods in the urban core will no longer be sustainable. Many companies have transitioned fleets to full-sized vans to minimize the need for large trucks, and some are going so far as exploring bicycles, drones and autonomous vehicles to complete the delivery task.

However, whether it’s a box truck or a drone delivering the package, each of these methods must be accommodated at the last-mile distribution facility. Should the facility need to increase the number of vehicles accessing the site or the amount of product being held – it could force an increase in square footage. Additionally, some companies are reusing old buildings as a way to solve for more storage space or to establish micro-fulfillment centers to meet the needs of the area, but this will require an analysis from the beginning to determine if the building is capable of sustaining such use. Both of these ideas warrant a good, efficient design.

Curbside pickups

To cut down on delivery time, curbside pickup allows companies to deliver straight to the vehicle. This now popular method requires existing stores to provide means of temporary storage until the customer arrives. In many cases, stores have opted to retrofit back of house areas as temporary storage to not reduce the sales floor. However, this reduces office, circulation, or general storage areas which could have operational impacts. When cold or frozen products are involved, additional refrigeration is required for quick and easy access. Depending on the store’s need, this can be solved by building new, smaller walk-in cooler and freezer boxes or installing new refrigerated/frozen case equipment. Both would require electrical and potentially HVAC improvements. From the customer’s perspective, the store is operating like usual, but portions of it have been redesigned.

“Pop-up” delivery sites

More and more companies and brands are exploring ‘pop-up’ fulfillment centers in an attempt to place the products into the customers hands as soon as possible. These pop-up centers require the company to think like a customer and also seek innovative locations to install new technology.

Pop-up centers can range from semi-permanent installations, such as taking over a shuttered retail or grocery store, or locker systems installed inside high-traffic areas. For example, many companies are installing locker systems in areas where their customers might shop too, such as gas stations, convenience or grocery stores, or inside train or bus stations. This requires collaboration within the existing site but also modifying floor plans and site layouts to accommodate the new system.

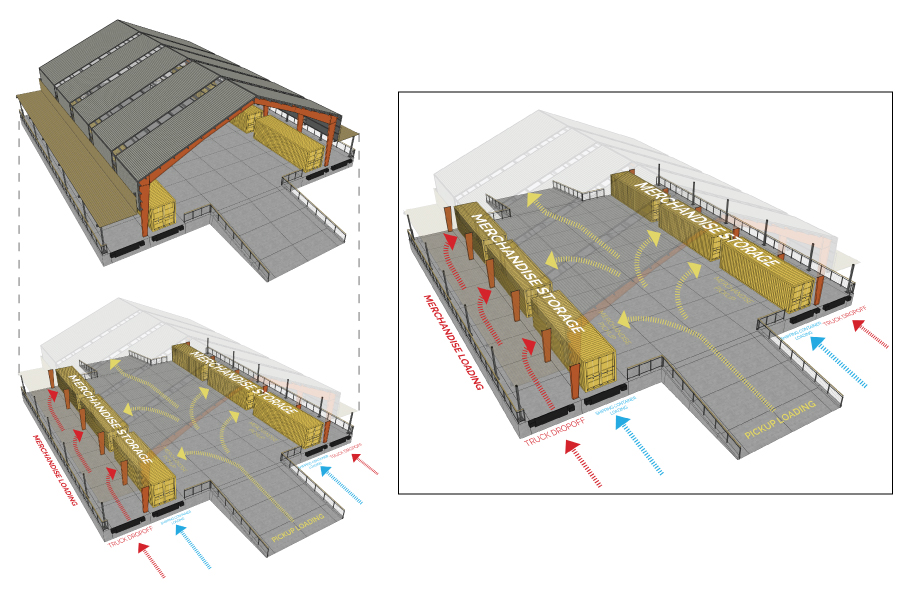

Additionally, we are working with brands to design and install temporary pop-up locations for delivering goods, using shipping containers, tent systems and other equipment in the designs. These ‘pop-ups’ can be located in large parking lots or in other available vacant real estate. Owners need to consider jurisdictional requirements and other codes-related accessibility mandates when approaching these types of projects.

Brands are becoming increasingly innovative as it relates to getting their goods into the hands of their customers, and as such, we’ll continue to see new designs emerge to support these delivery methods. With the industrial and fulfilment sector shifting rapidly, the impact on supply chains stands to be significant. Overall, no matter the delivery method or type, that ‘last mile’ is having a direct correlation to the evolution of the distribution center.

About the author:

Robert Ciston, AIA, is a Vice President and Principal at BRR. Since joining the firm in 1998, Robert has been instrumental in leading one of BRR’s studios, working on a range of national and local projects, and completing a variety of project types. His involvement and leadership currently spans the design and management of more than two dozen unique clients. Additionally, Robert continually works to develop processes and tools that maximize production workflow. He led the creation of our custom project management program, and continues to provide executive-level leadership for the tool’s evolution and capabilities. Email him.