Designing for the New Age of Warehouse Automation

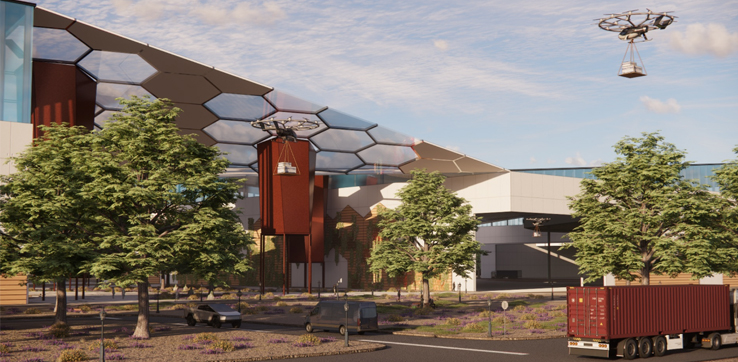

Industrial warehouses are complex projects, and innovative design is among the key elements vital to their long-term success. As industrial automation of these types of facilities continues to evolve, so do the expectations placed on modern warehouses and the results they’re required to produce.

Despite automation being crucial for efficiency, combining technology and design often stalls the integration process. Whether clients seek facilities that are new builds, retrofit installs, tenant improvements and more – its clear warehouse projects require operational resilience, speed and scalability.

Optimizing the Warehouse Layout

When automation is considered in any warehouse project, it needs to be top of mind from day one, instead of being treated as an afterthought. Before a warehouse project begins, it’s important to include a pre-planning phase which establishes the timeline for research, codes analysis and power requirements for automation equipment. This phase allows architects and clients to work together as a team and create a layout that not only works – but can be repeated across multiple projects.

The most efficient layouts reduce travel distances, redundancy and dead space while prioritizing vehicle traffic patterns, employee paths, equipment clearances and sightlines.

It’s especially important to consider the layout not as a spatial exercise, but as an operational safeguard. Modern automation demands architecture that’s built for efficiency, flow and predictability in order to save cost and increase warehouse capacity.

Permitting that Keeps Projects Moving

Warehouse automation projects often involve tight timelines, phased construction and equipment, which require orders to be submitted well in advance. In these cases, permitting can either support the momentum of a project or stall it entirely.

Finding an architect that knows how to communicate with plan reviewers is crucial to warehouse automation projects. For some jurisdictions, this type of technology is still a new frontier. When the architecture team collaborates with the jurisdiction and makes these individuals a part of the project team, it allows automated warehouses to move efficiently through phased approvals or specialized inspections.

During the permitting process, owners should consider hiring a design team that can keep projects moving forward and eliminate surprises. By keeping a project on track through permitting, it ensures that the necessary approvals align with equipment deliveries, occupancy milestones and integration schedules.

Creating Repeatability and Rollout Readiness

When it comes to automated facilities, companies often expand their portfolio across the country and do not limit themselves to one facility. Larger programs require systems and processes that are consistent, well-documented and scalable. Establishing repeatability doesn’t limit customization – it instead lays the foundation for growth and rollout readiness.

Creating a program of automation-equipped warehouses often yields the best results when the design team can develop internal design standards, apply lessons learned across sites, implement standardization and deliver consistently quality across projects nationwide.

Companies that invest in these design standards early on are usually able to deliver projects faster and with a stronger alignment between design, construction and operations teams.

Looking Forward

The architectural design of automation-driven warehouses and fulfillment centers is not limited to efficiency or aesthetics. Good design creates buildings that support operations, protect uptime and scale with demand in mind.

Refining these elements sets the stage for long-term operational success and allows industrial warehouses to perform better and be built smarter. By considering automation at the forefront of design, it empowers these spaces to function as valuable assets for the company.